Welcome to the House of Fun...

…Welcome to the Lion’s Den, Temptation’s on its way…

…And boy do we have temptation on the cards! We truly do love Madness in every sense!

So really, what is a Post-Production Studio? How does this all work?

Honestly, it’s whatever our clients require it to be and those that understand the concept conjure up some brilliant challenges for our studio to work on.

The post-production product itself is simple. Take existing “ordinary” stock of a product and embellish it to have a brand new USP for the existing market. How to get a product from the ordinary to the extra-ordinary is where we come in. We have a studio equipped with not only state- of-the-art print technology, but also a host of carefully curated older machinery that would be seen as redundant in most instances. We have given these machines new and, in some cases, highly unlikely, wonderful purposes.

Have a read through some of the general processes that we house in our arsenal and, if any of them spark an idea, please get in touch and lay down a challenge or two.

SCREEN PRINTING

Screen Printing is core to not only our Post-Production Studio, but also our general Print Solutions. It is one of the most diverse methods of printing and a joy to refine as a skill. Over the years we have used the method to print on some obscure products and media.

This is a process that is highly adaptable, we have printed various plastics, sourced hyper eco-friendly inks and even printed food stuffs on an incredibly rare occasion. We commonly use the following processes in the studio which could enhance your products:

- Screen Printed Vinyl LP Records. (Onto a blank B-side, or grooved B-side where the B-side is no longer to be playable)

- Screen Printed PVC or Polypropylene Sleeves

- Screen Printed Overprints onto existing card or paper packaging. Including capacity items such as boxes.

- Screen Printed textiles to be, or already fitted into packaging.

- Screen Printed promotional goods & clothing, often used as add-ons.

- Screen Printed Posters

- Screen Printed Fold Overs to wrap around Products.

- Screen Printed Shrink Wrap. (On Products!)

CUTTING

Cutting sounds like the simplest thing to action and yet we still have projects where, at first glance, it all looks simple enough but the moment one tests a blade on the substrate singing “first cut is the deepest”, a change of approach is evident and the vocal tone takes a steep nose dive as some head scratching begins.

We have 12 (and a half) different types of cutting machines as well as the traditional use of hands and each one skins the cat* differently. Sometimes in multiple fashions.

One major skill we have up our sleeves is a space in which to design, build and tweak, tweak and re-tweak jigs for our processes. A huge number of ultra unique products require an ultra-unique jig or two so that the project can be executed at enough speed to be commercially viable.

We die cut, laser cut, wheel cut, hot knife, plot, shear, trim, scalpel, perforate, jib (as well as jab), thread, poke, stick, stab, podge, slice, dice, snip, chop, slash, rip, sever, pierce, carve, cleave and sometimes we do even resign to hack, but all very carefully!

*Please note, we love cats and do not skin them.

Sticky Stuff...

Resins, Epoxies, Plastics, Metals & Glues. A lot of our more ornate embellishments utilise a mix of processes from castings, to pressings, to 3D printing and beyond. We keep a locked COSHH cabinet that only the most experienced ALBOM-ists have the key for, and we guard it well.

Products that are amplified using these methods involve precise planning and careful execution. We are well versed in our mould making, resin pouring, torch branding, acid etching, and a bunch of other science-come-crafty-ing processes. We will always endeavour to find a way that best suits the task at hand, even if we must learn something to do so. Especially if we must learn something to do so.

We have produced many an idea where the innovator had all but lost hope of it being realised, only for us to leap at the chance to learn something new on the journey. So, if you’ve just remembered that idea you’ve been dwelling on since last Tuesday circa 1985. Get in touch and we will be all too happy to join the journey.

Embracing the Digital Age

Digital technology is an odd topic to talk about on some projects and today’s world finds itself in a generational jumble. The general population can be indecisive or in debate as to what constitutes a digital process in this early part of the millennium. After all, there is so much technology around us every day, the term “digital” and “modern” can get a little jumbled.

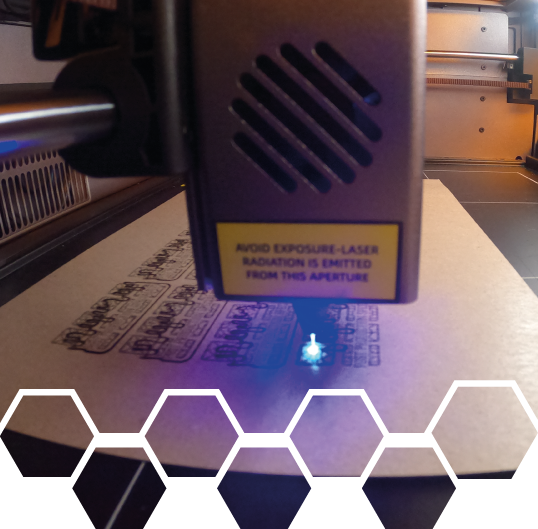

We are by no means purists in any direction at ALBOM45 and spend a great deal of time researching and developing our range of crafts and combining them with new technology. Our studios house several cutting-edge digital technologies. They range from larger direct-to-substrate UV printers, handheld micro printers and high definition giclee inkjet printers to CNC routers, lasers, plotters and 3D resin and fillament printers. We are also fortunate to have production floor level access to some of the world’s most revolutionary machines and the operators who have mastered them.

We know that a combination of the old and new benefits our work and permits us to embrace an extensive array of project work. Often clients request us to include a technology or process that is new to us, or that is young in its own development. These projects excite, as well as humble us and often award all parties the opportunity for new partnerships. After all, sometimes it’s about the journey behind the product that gives it value.

And the rest of it…being, all the things we have at our disposal that don’t really fit into any categories, simple explanations or that we just like to keep hidden up our sleeves. The information on this page is really an introduction to our passion for process and is intended to demonstrate, in a small window, our excitement for making, manufacturing and general madness. This is what makes our team great for this job. There is no sales speak, no pressure, just a collaborative, inviting studio that welcomes your project. If you have a project, or an enquiry on a process that we may have or may invest our learning into, please get in touch.